The Premier Thermal Spray Services in Malaysia

H & T Industries stands as a pioneering force in the realm of thermal spray coatings. With a legacy of innovation and a strong reputation, we have played a significant role in advancing this field and are recognized as a leading provider of thermal spray services.

Read moreRead less

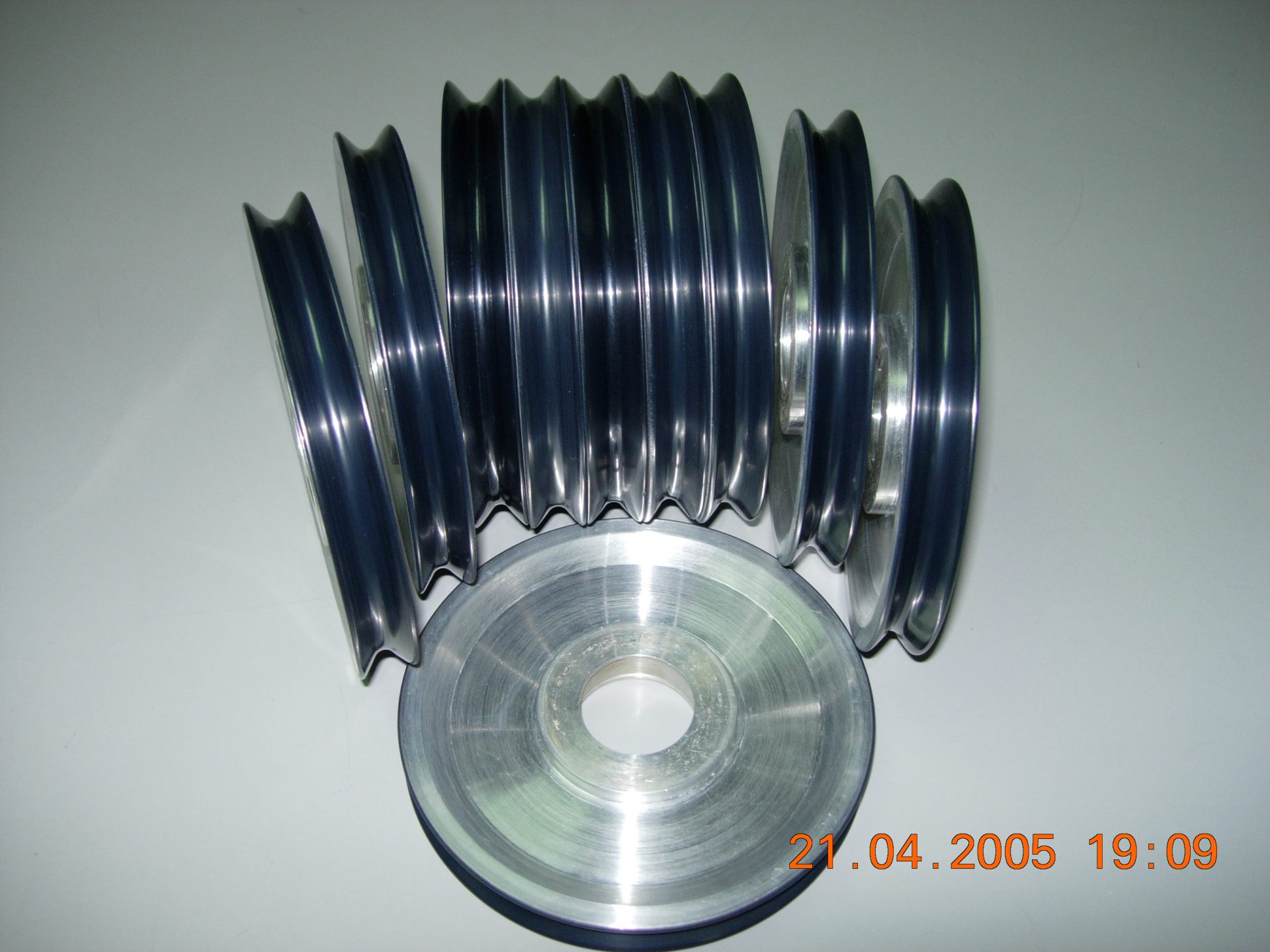

Our range of services, including the HVOF and Thermal Arc Spray, reflects our commitment to quality and customer satisfaction. We focus on improving the durability and efficiency of your components using advanced thermal spray technology.

Thermal Spray Processes

Want to prolong the lifespan of your metal components without compromising their strength? Thermal spray processes offer great solutions for surface property enhancement in countless industrial uses. This new method allows us to deposit protective coatings that can significantly enhance component life while stimulating enhanced performance in harsh conditions.

Best Thermal Coating Techniques

With regard to coating applications, thermal spray technology delivers high-specification performance on every type of component with an incredible range of materials. The best technique for your specific application depends on a number of factors like substrate material, service conditions, and performance requirements.

High-Velocity Oxygen Fuel (HVOF) Spray

HVOF deposits extremely dense, highly bonded coatings with low porosity and superior wear resistance. HVOF process propels particles of powder to supersonic velocities in a combustion chamber and creates a hard coating with superior adhesion strength.

Did you know how the components treated with HVOF always function better than conventional coatings in abrasive conditions? The difference is truly noticeable, especially when conventional solutions wear out earlier in some applications.

Metal Flame Spray

For applications where cost is a consideration but corrosion resistance is necessary, metal flame spray is an excellent value. This process heats wire or powder feedstock in an oxygen-fuel gas flame and then propels the molten material onto the substrate with compressed air. It’s best suited to larger pieces where even coverage is more important than absolute thickness.

Metal Arc Spray

As soon as you need higher throughput rates and heavier coatings, metalizing through arc spray becomes extremely beneficial. Two wires that are electrically charged generate an arc which melts the material and expels it with the help of compressed air.

It produces a strong bond coating along with medium density at production levels that enable your projects to be completed on schedule and within your budget.

Benefit of the Hot Metal Spray Coating

Hot metal spray coating has many advantages that are more and more demanded by Malaysian industries. Here are some of the examples:

- Extended Component Life: The coatings significantly reduce wear, erosion, and corrosion, often doubling, tripling, or even quadrupling service life.

- Restoration of Dimensions: Thermal spray restores rather than replacing worn components to original dimensions or better.

- Improved Performance: Thermal insulation, reduced friction, greater hardness, or enhanced abrasion resistance improve operating efficiency.

- Substrate Protection: The substrate is protected from environmental factors that would otherwise lead to rapid degradation.

- Less Downtime: Components last longer between maintenance cycles, keeping your operations at peak levels.

- Cost Savings: Preserving component life and repairing rather than replacing parts translates into huge long-term savings.

- Environmentally Friendly: Thermal spray’s capability to preserve component life translates into less material usage and waste—something we’re growing more conscious of in Malaysia’s growing industrial bases.

Thermal Coating Applications

Thermal spray technology is broadly applied to enhance surface characteristics across a range of applications. Ever wondered how some components appear to survive impossibly hostile conditions? The reason may be found in sophisticated thermal spray coatings designed for particular operating needs.

Many important industries take advantage of these advanced spraying methods:

Automotive: Cylinder bore, valve parts, and exhaust system wear protection and thermal management.

Oil & Gas: Chemical corrosion protection and oxygen protection for valves, pumps, and offshore equipment used in Malaysia’s challenging sea environment.

Power Generation: Boiler tubing, turbine parts, and heat exchangers enjoy necessary high-temperature oxidation and erosion protection.

Manufacturing: Paper mill rolls, textile machinery, and printing equipment last longer with specialized coatings.

H & T Industries – Advanced Thermal Spray Solutions Near You

Our experienced team possesses the knowledge and expertise to treat your components with precision and care while using state-of-the-art thermal spray technology. This results in longer-lasting components, lower maintenance and replacement costs, and improved overall reliability and cost-effectiveness for your business.

When you choose H & T Industries for your thermal spray needs, you are selecting a partner dedicated to excellence and success, offering advanced thermal spray solutions such as tungsten carbide coating.

Contact us today to discuss your project requirements and experience the benefits of our advanced thermal spray solutions.